by John O'Keefe-Odom

AgXphoto.info

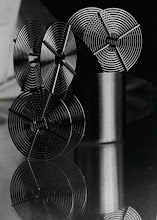

The neoprene grip was built of 3 layers of 2mm neoprene. The first layer contains two notches to clear brass shim pneumatic valves built into the zoom housing. These valves are normally concealed by the textured rubber grip, and permit the zoom assembly to extend or contract without creating or breaking a partial vacuum. The notches in the first layer of neoprene permit the zoom to be used as it was designed; the lens extends and contracts freely, as it does with the OEM grips.

To remove the OEM textured vinyl/rubber grips, I just rolled them off. Carefully pluck up one edge and roll it back onto the outside of the grip itself. Work the whole edge over onto itself, and then slowly roll the grip down towards the narrowest end of the lens barrel. With common sense and simple observation, you should be able to tell right away if the grip is going to clear the rest of the lens structure.

This way, I was able to remove the OEM grip without damaging it. So, it could be reinstalled some time in the future, if desired.

First layer of custom neoprene is wrapped completely around the barrel, and then onto itself for a distance of approximately 1" (2.5 cm). At that seam, the neoprene is cemented to itself, so that no adhesive binds the grip to the lens assembly. The grip is held in place by form-fitting friction. This means that another user can have the grip removed easily, and reinstall the OEM textured rubber grip if desired. The neoprene grip was not designed to be repeatedly removed or swiftly interchanged with the OEM grips; but we have followed a strong trend in camera modification and repair: the modification is reversible, and causes no permanent change to the original structure.

The choice of cement used was simple rubber cement. I found that the rubber cement did the best no-fuss job of securing the neoprene foam to itself. Along the way, I looked into Loctite brand adhesive, but there was a warning on the package specifically against using it on neoprene foam.

I had come across the Loctite because I was interested in installing even thicker, more durable padding on the grips. Initially, I wanted to cement a layer of rubber around the neoprene, and then encase that, too, in a layer of neoprene.

I found first of all that my initial estimates for the thickness of the rubber strip were too generous. I had to scale back my design idea from 1/2” to 1/4” thickness.

Good thing I did, because the rubber stripping I received was tough stuff. The 1/2” thickness never would have worked. As it was, after a brief trial, I decided to scrap the rubber strip idea. It simply could not be cemented to the base layer of neoprene with the durability I thought the project demanded. I may revisit this concept in the future; but, for now, it was better to stick with what was working and on hand.

With the thicker rubber strip not working as planned, I still had that ugly overlapping seam to deal with. Already, the zoom lens barrel felt good in my hands. So, I put on two more layers of neoprene over that.

One layer of neoprene was added on, and had to be redone. I learned a shocking lesson with the masking tape and the rubber cement. I was using masking tape to protect the painted portions of the barrel from unwanted adhesive. Good enough. But then, remembering what it was like to handhold the first layer of foam until it dried, thought that I would do well to wrap the next neoprene layer in masking tape until it dried. What a mistake. Apparently, the fumes from the setting rubber cement must have somehow penetrated the neoprene foam or in some way have come into contact with the adhesive side of the masking tape. What was normally a good performing tape left an unsightly goo of stray adhesive as I pulled away the strips I had put in place to hold down the neoprene layer while it dried. I won’t do that again.

The last layer of neoprene was a success; and in it, I incorporated other lessons I had learned along the way. First, I coated the neoprene foam with rubber cement twice. The first layer is readily absorbed by the foam, and needs to set in a little. Otherwise, the foam layer will absorb most of the glue, and not use the glue to bind itself in the lamination.

Next, I was closer on trimming the ends. Each time I had wrapped the neoprene before, I had carefully measured out where I wanted the layer to end. But, the layer expands slightly in contact with the glue; also, there is some stretchiness to the foam. Overall, I found that a 1/4” allowance was called for; that is, measure out the circumference the neoprene must envelope, and then reduce that distance by 1/4” to accommodate the stretch factor in the foam. This will leave the foam with some stretch and flexibility, but taut enough to make a smoother seam.

The custom neoprene grip, with its 6mm thick foam housing, provided a layer of buffering not found in the OEM design. For an active photographer, like a young college student, for example, scrambling over rocks, letting the camera ride on the passenger seat of the car as they zip off to the next destination, or any number of dynamic activities; for an active photographer, a little bit of neoprene padding can go a long way.

If you choose to build one of these for your telephoto lens, I would suggest that you evaluate the existing structure with care. But, I found making this rewarding.

AgXphoto.info

The neoprene grip was built of 3 layers of 2mm neoprene. The first layer contains two notches to clear brass shim pneumatic valves built into the zoom housing. These valves are normally concealed by the textured rubber grip, and permit the zoom assembly to extend or contract without creating or breaking a partial vacuum. The notches in the first layer of neoprene permit the zoom to be used as it was designed; the lens extends and contracts freely, as it does with the OEM grips.

To remove the OEM textured vinyl/rubber grips, I just rolled them off. Carefully pluck up one edge and roll it back onto the outside of the grip itself. Work the whole edge over onto itself, and then slowly roll the grip down towards the narrowest end of the lens barrel. With common sense and simple observation, you should be able to tell right away if the grip is going to clear the rest of the lens structure.

This way, I was able to remove the OEM grip without damaging it. So, it could be reinstalled some time in the future, if desired.

First layer of custom neoprene is wrapped completely around the barrel, and then onto itself for a distance of approximately 1" (2.5 cm). At that seam, the neoprene is cemented to itself, so that no adhesive binds the grip to the lens assembly. The grip is held in place by form-fitting friction. This means that another user can have the grip removed easily, and reinstall the OEM textured rubber grip if desired. The neoprene grip was not designed to be repeatedly removed or swiftly interchanged with the OEM grips; but we have followed a strong trend in camera modification and repair: the modification is reversible, and causes no permanent change to the original structure.

The choice of cement used was simple rubber cement. I found that the rubber cement did the best no-fuss job of securing the neoprene foam to itself. Along the way, I looked into Loctite brand adhesive, but there was a warning on the package specifically against using it on neoprene foam.

I had come across the Loctite because I was interested in installing even thicker, more durable padding on the grips. Initially, I wanted to cement a layer of rubber around the neoprene, and then encase that, too, in a layer of neoprene.

I found first of all that my initial estimates for the thickness of the rubber strip were too generous. I had to scale back my design idea from 1/2” to 1/4” thickness.

Good thing I did, because the rubber stripping I received was tough stuff. The 1/2” thickness never would have worked. As it was, after a brief trial, I decided to scrap the rubber strip idea. It simply could not be cemented to the base layer of neoprene with the durability I thought the project demanded. I may revisit this concept in the future; but, for now, it was better to stick with what was working and on hand.

With the thicker rubber strip not working as planned, I still had that ugly overlapping seam to deal with. Already, the zoom lens barrel felt good in my hands. So, I put on two more layers of neoprene over that.

One layer of neoprene was added on, and had to be redone. I learned a shocking lesson with the masking tape and the rubber cement. I was using masking tape to protect the painted portions of the barrel from unwanted adhesive. Good enough. But then, remembering what it was like to handhold the first layer of foam until it dried, thought that I would do well to wrap the next neoprene layer in masking tape until it dried. What a mistake. Apparently, the fumes from the setting rubber cement must have somehow penetrated the neoprene foam or in some way have come into contact with the adhesive side of the masking tape. What was normally a good performing tape left an unsightly goo of stray adhesive as I pulled away the strips I had put in place to hold down the neoprene layer while it dried. I won’t do that again.

The last layer of neoprene was a success; and in it, I incorporated other lessons I had learned along the way. First, I coated the neoprene foam with rubber cement twice. The first layer is readily absorbed by the foam, and needs to set in a little. Otherwise, the foam layer will absorb most of the glue, and not use the glue to bind itself in the lamination.

Next, I was closer on trimming the ends. Each time I had wrapped the neoprene before, I had carefully measured out where I wanted the layer to end. But, the layer expands slightly in contact with the glue; also, there is some stretchiness to the foam. Overall, I found that a 1/4” allowance was called for; that is, measure out the circumference the neoprene must envelope, and then reduce that distance by 1/4” to accommodate the stretch factor in the foam. This will leave the foam with some stretch and flexibility, but taut enough to make a smoother seam.

The custom neoprene grip, with its 6mm thick foam housing, provided a layer of buffering not found in the OEM design. For an active photographer, like a young college student, for example, scrambling over rocks, letting the camera ride on the passenger seat of the car as they zip off to the next destination, or any number of dynamic activities; for an active photographer, a little bit of neoprene padding can go a long way.

If you choose to build one of these for your telephoto lens, I would suggest that you evaluate the existing structure with care. But, I found making this rewarding.

# # #

No comments:

Post a Comment